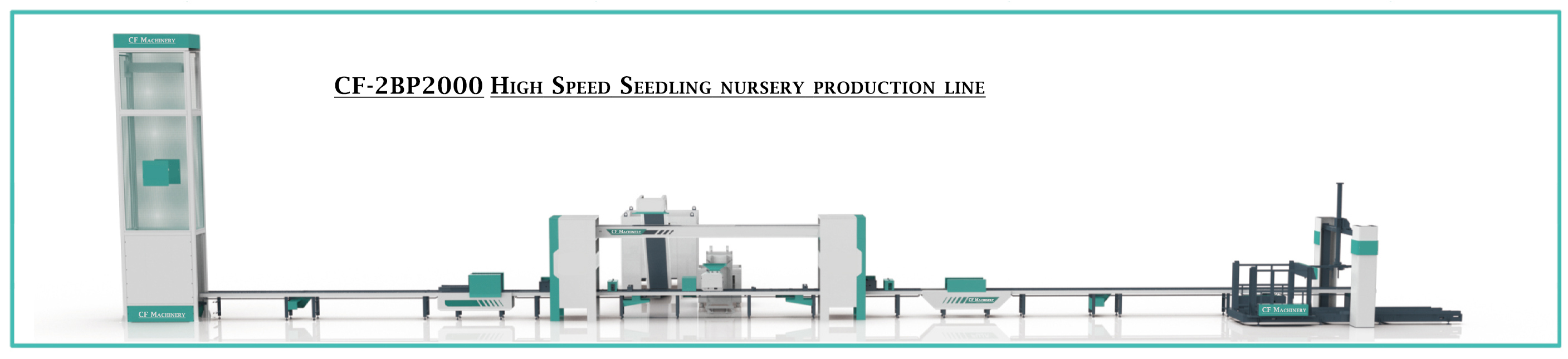

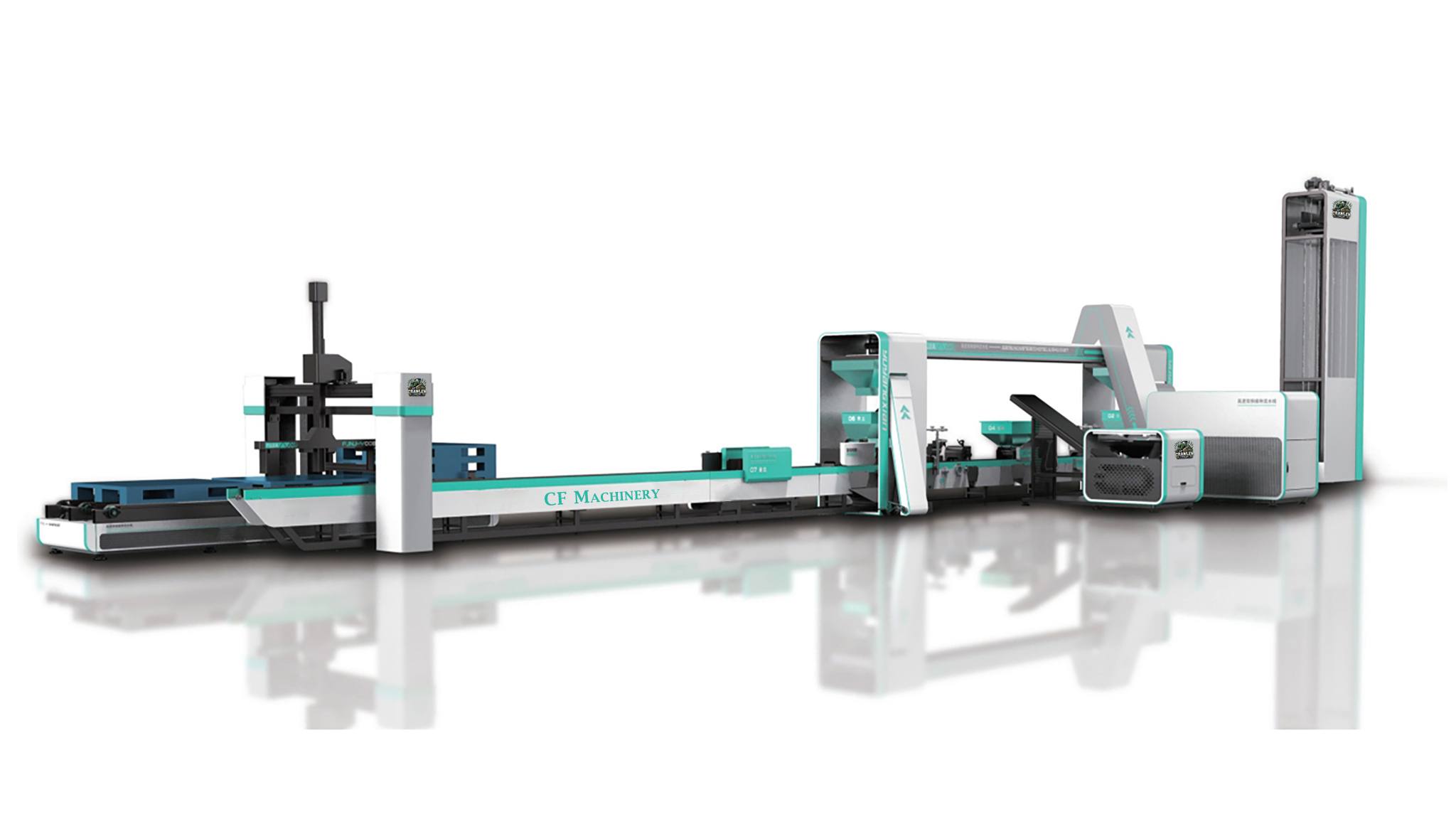

The CF-2BP2000 seedling nursery production line integrates an intelligent control system, time-series sensing system, and real-time operational data monitoring. It can be equipped with auxiliary devices to complete the following processes in one continuous workflow: Tray laddering, Tray feedering, Soil dispensing, Watering, Seeding, Chemical application(Disinfection),Seeds covering with soil, Tray stacking (adjustable for 1–5 layers), Automatic soil and seed supply, Residue recycling, Palletizing etc.

Technical Specifications

1.Dimensions (L×W×H): 8970×630×1280mm (±2%)

2.Hourly Output: ≥2,000 trays/h

3.Soil-Spreading Uniformity: ≥90%

4.Seeder Type: Single-groove wheel sowing shaft

5.Seeding Rate Adjustment: Inverter-based stepless regulation

6.Missed Spot Rate: ≤2%

7.Seeding Range: 60–300g/tray

8. Soil-Covering Uniformity: ≥90%

9. Soil-Leveling Method: Rotating spreading cage

10.Conveyor Drive Type: Belt + chain transmission

11.Watering Uniformity: 90%

12. Workflow: Soil dispensing → Watering → Seeding → Seeds covering with soil → Chemical application(Disinfection)

13.Total Power: ≤1.2kW

14.Remote Monitoring: Real-time data access for operational insights.

15.Digitized & Automated Operation: Supports speed adjustment, workload tracking, and stacking layer control via an integrated interface.

Intelligent Control System

1.Soil Dispensing & Covering (Seeds): Tray detection, Automatic startup/stop,Soil volume sensing and external conveyor control.

2.Watering: Tray detection, Automatic startup/stop.

3.Seeding: Tray detection, Automatic startup/stop.

Application Scenarios

✅ Commercial/Industrial Nurseries: Scale production for seasonal demand.

✅ Organic Farms: Ensure chemical-free, uniform seedling growth.

✅ Smart Agriculture Hubs: IoT-enabled for integration with farm management systems.

✅ Government Projects: Supports food security initiatives through standardized, high-yield outputs.

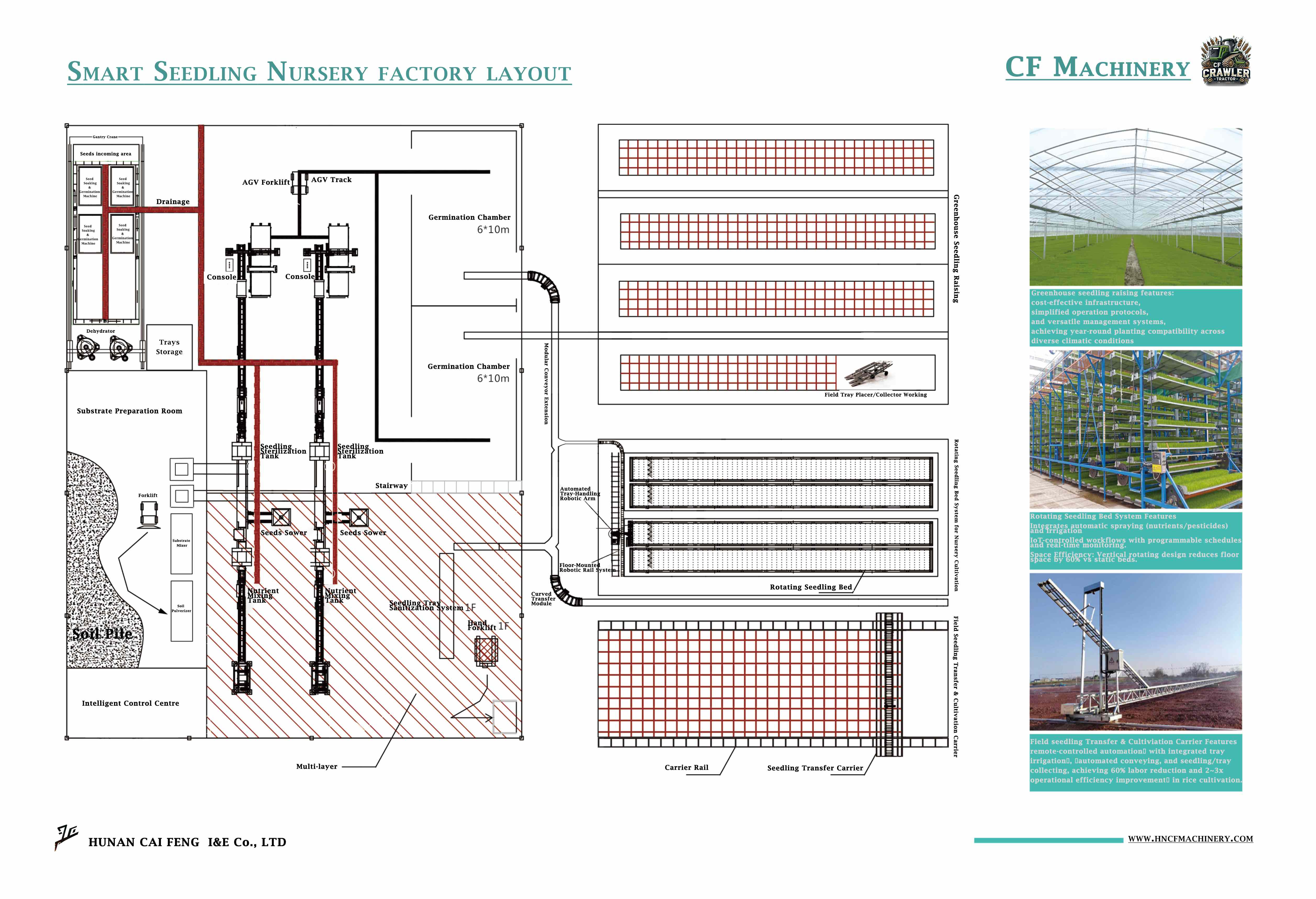

Seedling Nursery Base Case Layout

More Auxiliary Equipments Explore