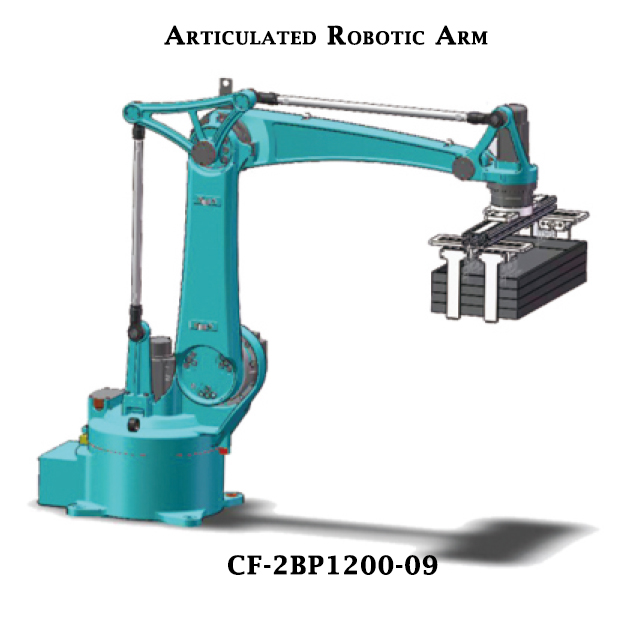

The CF-2BP1200-09 Articulated Robotic Arm is a cutting-edge automation solution designed to streamline tray handling in multi-functional seeding production lines. With **PLC program control** and seamless integration with sowing equipment, it ensures precise, efficient, and reliable operation for large-scale agricultural workflows.

Key Features

- Ultra-Precise Handling: Achieves **±0.08mm repeat positioning accuracy**, ensuring consistent tray placement.

- Heavy-Duty Performance: Lifts up to **25kg payload** and handles **4 seedling trays per grip**, maximizing productivity.

- Robust Construction: Built with a **1770mm arm length** and **≥130kg sturdy frame** for durability in demanding environments.

- Smart Control: PLC system enables automatic or manual start/stop, syncing perfectly with seeding machinery.

- Adaptive Operation: Functions reliably in temperatures **0-45°C** and humidity **20-80% RH** (non-condensing).

Applications:

- Automates **tray pickup, transfer, and placement** in seedling, vegetable, or herb production lines.

- Reduces labor costs and minimizes human error in high-volume operations.

Ideal for agribusinesses seeking to enhance automation, this robotic arm boosts efficiency while maintaining precision. Compatible with diverse seeding systems for year-round use.

Upgrade your production line with precision robotics—contact us for a customized solution!