Automated Seedling Production Lines: Precision & Efficiency Redefined

Jul 13, 2023

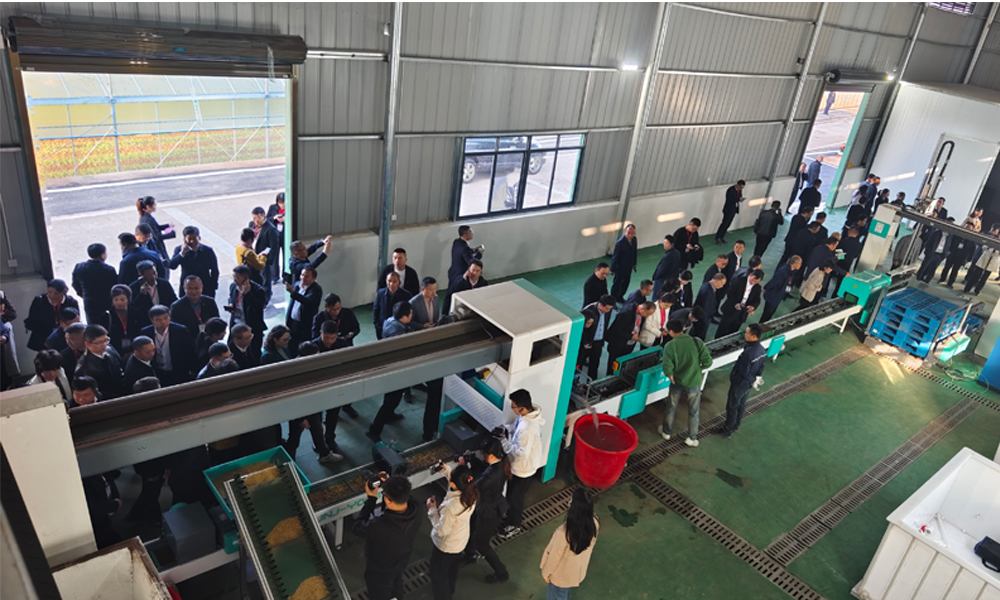

Automated Seedling Production Lines: Revolutionizing Agricultural Efficiency

The global demand for automated seedling production systems is surging, driven by labor shortages and the need for precision agriculture. These systems integrate robotics, AI, and IoT to optimize seedling cultivation. Below are the core features and competitive advantages:

1. Product Features

Fully Automated Workflow: Seeding, tray filling, watering, and environment control (temperature, humidity, light) managed without manual intervention.

Precision Sowing: Laser-guided seed placement achieves 99% accuracy, reducing seed waste by 40%.

Modular Design: Scalable for small farms (<1 ha) to industrial operations (>50 ha), with throughput up to 12,000 trays/day.

Smart Monitoring: IoT sensors track soil moisture (±2% accuracy) and adjust nutrient dosing in real time.

2. Performance Advantages

Labor Savings: Reduces manual labor by 70%, cutting operational costs by $2,000/acre annually.

Yield Boost: Uniform seedling growth improves crop yields by 20-35% compared to traditional methods.

Resource Efficiency: Water usage reduced by 50% via closed-loop irrigation; energy consumption lowered by 30% with solar integration.

Disease Control: UV sterilization and HEPA filters minimize pathogen risks, raising seedling survival rates to 98%.

3. Market Adoption Drivers

Labor Shortages: Japan’s agricultural workforce declined by 55% since 2000, accelerating automation adoption.

Government Support: China’s “Smart Agriculture” subsidies cover 40% of equipment costs; EU’s CAP funds promote sustainable tech.

Climate Resilience: Systems maintain optimal conditions during droughts or floods, securing harvests in unstable climates.

4. Regional Innovations

Asia-Pacific: China’s Jiangsu Minjie Automation leads with AI-powered seedling lines priced at $120,000/unit (ROI: 2 years).

Europe: Dutch firm Viscon Group integrates vertical farming tech, achieving 18% faster germination.

Americas: TTA (US) dominates greenhouse automation with hybrid solar-diesel systems for off-grid farms.

5. Future Trends

AI Optimization: Machine learning predicts growth patterns, adjusting light spectra to enhance photosynthesis by 25%.

Blockchain Traceability: Seed-to-harvest data logging ensures compliance with EU/US organic certifications.